Seeking an efficient construction solution? Shotcrete is rapidly gaining favor for its quick application and structural strength. Ideal for various projects, from stabilizing slopes to crafting artistic designs, shotcrete merges speed with durability. Discover the practical benefits and cost-savings that could make shotcrete the smart choice for your next build.

Key Takeaways

- Shotcrete stands out for its versatility, durability, and cost-effectiveness, enabling rapid project completion and reducing labor costs while creating strong, enduring structures.

- Applicable across diverse scenarios, shotcrete is adept for basement stabilization, custom swimming pool creation, and building robust retaining walls, showcasing its versatility and adaptability.

- The shotcrete process comes in two main forms: dry and wet, with the dry mix allowing for economy and precision, and the wet mix favoring speed and consistency, suitable for different project scales and requirements.

Shotcrete Advantages

Shotcrete captivates the construction industry with its powerful combination of adaptability, longevity, and financial efficiency. This material has transformed the construction landscape by seamlessly conforming to complex designs and challenging conditions. Quicker application and hardening processes mean projects reach completion more quickly, simultaneously yielding significant savings in workforce expenses—benefits that establish shotcrete as an economically attractive option for diverse building requirements.

The strength of shotcrete is unrivaled, even as it boasts flexibility. There’s no compromise on robustness. Shotcrete-engineered buildings are not only capable of bearing substantial burdens, but also excel in enduring over time without succumbing to degradation. Thus, shotcrete stands at the forefront as a quintessential material innovation that expertly fuses versatility with durability and cost-efficiency into one integrated solution for today’s architectural demands.

Versatility

When traditional construction techniques fall short, shotcrete often steps in without forcing significant concessions. It is well-suited for projects that demand smooth curves or precise right angles while accommodating a variety of factors such as the particularities of location and terrain. This versatility distinguishes shotcrete from other materials. Its prowess lies in constructing at multiple levels, reaching into spaces with restricted access, and flawlessly assuming any shape imparted by the mold or surface it contacts.

Consider an instance where both safety concerns and aesthetic value hold equal importance within a space marked by complex angles demanding to be addressed—here, shotcrete emerges as an excellent solution. As a method requiring minimal framework support compared to conventional methods, it invites design options otherwise unattainable with standard concrete applications. Both companies and homeowners can confidently map out their plans knowing that the adaptability of shotcrete not only meets but frequently surpasses what they envision for their project’s successful completion.

Durability

The necessity for long-lasting materials in construction is imperative. These materials must withstand the passage of time, bear the load from soil and rocks, and resist continuous exposure to water and chemicals. Shotcrete meets these requirements with its formulation that includes Portland cement—known for its robustness—and has an exceptional capacity to endure heavy weights without failing. By integrating steel rods, mesh or fibers into this shotcrete mixture, it significantly enhances structural integrity, elevating durability.

In terms of seismic fortitude, shotcrete’s ability to reinforce building resistance against earthquakes is evident. This characteristic ensures enhanced safety and extended life span for structures situated in earthquake-prone regions or where extreme weather conditions prevail. Esteemed is the dry shotcrete process’s superior bond strength. It guarantees a firm connection between layers of concrete, which contributes indispensably to sustaining the longevity of constructions undertaken using this material.

Cost-Effectiveness

Examining the cost implications of construction undertakings, it is crucial to consider not just initial expenses. Shotcrete presents multiple advantages over time that contribute to its economic efficiency.

- Due to shotcrete’s impressive durability, there’s less necessity for regular refurbishments.

- The diminished requirement for maintenance translates into sustained savings regarding upkeep expenditures.

- Both project managers and homeowners regard this as an essential consideration.

For sizable projects, particularly, the combination of safety benefits and financial economy becomes more pronounced thanks to bulk discounts, which render shotcrete a substantially attractive monetary investment.

Shotcrete Applications

Shotcrete is not a one-trick pony confined to a single type of construction project. Its versatility extends to a range of applications, each benefiting from its unique properties. Some of these applications include:

- Stabilization of basements and underground structures

- Crafting swimming pools with custom designs and long-lasting robustness

- Building retaining walls to manage slopes and erosion, taking advantage of its ability to form seamless coverage over complex shapes.

These examples illustrate the practicality of shotcrete in real-world scenarios, where its ability to adapt to various structural demands is invaluable. Shotcrete can be used for:

- Providing additional support against water infiltration in a basement

- Creating a bespoke in-ground pool in a backyard

- Constructing a retaining wall that retains soil and prevents erosion

Shotcrete proves to be an indispensable material for contractors and homeowners alike, especially when dealing with stone surfaces.

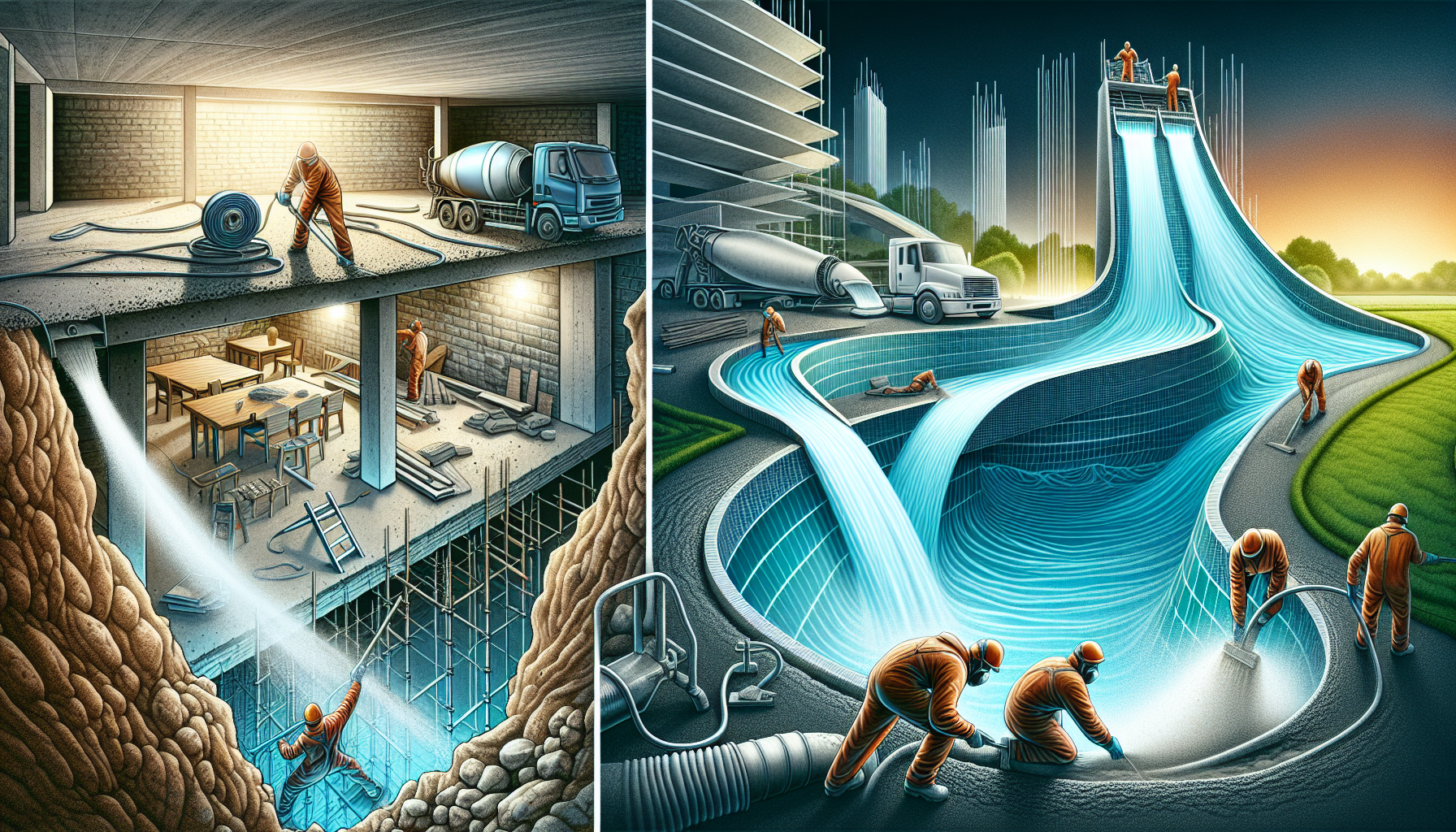

Basement Stabilization

The stability of basements is crucial for the overall solidity of a building, and maintaining this firmness is essential. Shotcrete serves as an efficient method to reinforce structural strength where it’s critical. The application process of shotcrete differs from that of regular concrete because it merges effortlessly with pre-existing materials, thereby bolstering both the sturdiness and the ability to repel water within the basement.

In regions susceptible to soil erosion or instances where water infiltration is a concern, this becomes especially significant.

Swimming Pools

Imagine a swimming pool customized to your precise desires – this is the marvel of using shotcrete in construction. Notoriously effective for crafting in-ground pools, it guarantees a seal that is both impermeable and exceedingly strong. During construction, the material is layered on by spraying, shaping the walls and curves of the pool with ease.

This technique presents an initial phase toward personalization. With gunite pools—a variety using shotcrete—any imaginable design can be brought to life through this method.

Retaining Walls

Retaining walls, such as gabion walls, serve a crucial role in preserving the integrity of sloping landscapes beyond merely enhancing their appearance. Shotcrete excels in building these types of walls because it is capable of:

- Adapting smoothly to the uneven surfaces typically found in these endeavors

- Providing continuous coverage that complements an array of reinforcement methods

- Delivering enhanced stability and superior protection against erosion.

Shotcrete Process and Types

Grasping the intricacies of the shotcrete process is crucial to recognize its extensive capabilities. The shotcrete technique splits into two predominant methods: dry and wet. With the dry method, all solid materials are combined prior to introducing water at the nozzle just as it’s being sprayed, which provides meticulous control over the mix proportions.

As for the wet method, it encompasses:

- Combining water with other components beforehand

- Enabling a more rapid deployment

- Minimizing material rebound off surfaces during application

- Aptness for grand-scale ventures where expediency is paramount.

Dry Process

Utilizing the dry shotcrete process offers cost-effectiveness and accuracy. This method involves propelling a stream of dry concrete mix through a hose directly onto the intended surface, providing enhanced command over the consistency of the mixture while also being more budget-friendly than traditional concrete approaches due to decreased reliance on formwork.

The application demands an adept nozzle operator who can ensure that the mix is administered meticulously, which enhances quality and simultaneously diminishes expenses.

Wet Process

Utilizing the wet process confers a unique array of benefits, particularly in terms of application rapidity and minimizing material rebound. Given that all components, water inclusive, are blended beforehand, the shotcrete is then conveyed via a hose and projected onto the target surface. This approach ensures uniformity within the mix and diminishes material wastage, rendering it an outstanding selection for endeavors necessitating swift and even distribution.

Choosing a Shotcrete Contractor

Choosing an experienced and knowledgeable shotcrete contractor is crucial for the successful completion of a construction project that uses this material. To avoid property damage, it’s critical to ensure that the contractor has a deep understanding of shotcrete application techniques. Contractors who have successfully managed diverse shotcrete tasks demonstrate their ability to solve problems efficiently and dependably.

Adhering strictly to safety regulations in the industry signals a responsible approach by the contractor toward on-site operations. Ensuring that they possess all required licenses and insurances adds an extra layer of security and comfort throughout the execution phase of your project. Obtaining feedback from past clients can provide insights into both workmanship quality and client service rendered by contractors.

Look to businesses such as SSG Pools when searching for a shotcrete partner, since they set benchmarks with their dedication to superior artisanship along with extensive guarantees on their services—qualities exemplary of what one should expect from such specialists in pool construction projects.

Shotcrete Maintenance and Repair

Homeowners can maintain the durability of their shotcrete structures by promptly addressing any signs that suggest foundational issues. Early intervention not only reduces stress but also saves a considerable amount on potential repairs. The dry shotcrete method is especially advantageous for its efficiency in executing small-scale patches or work that may need to pause intermittently, thereby reducing the waste of materials.

The strength and adherence of shotcrete are heavily dependent on appropriate curing practices, which entail moistening the material two to three times per day over a span of seven to ten days. If done with expert advice, homeowners could undertake this process themselves as part of DIY maintenance efforts – adding another layer to how cost-effective and manageable upkeep using shotcrete can be for repair purposes.

Shotcrete vs. Traditional Concrete

When you consider shotcrete as opposed to conventional concrete, there are distinct differences that stand out. With traditional concrete methods, the material must be mixed and poured into a mold or framework. This requires extra steps in preparation along with additional materials that act as molds and provide structural support while waiting for the concrete to harden. In contrast, due to its high-velocity application process, shotcrete immediately compacts upon contact, eliminating any necessity for mechanical vibration traditionally used to expel air pockets from within the mixture.

Although initially more expensive than standard concrete because of both specialized skills needed and specific equipment required for proper application, these higher upfront costs associated with shotcrete may pay off over time. The compacted nature resulting from how it’s applied creates a denser structure and improves durability potentially leading to greater long-term value when considering maintenance expenses associated with structures built using this material.

Environmental Impact of Shotcrete

The ecological effects of using shotcrete in current construction practices are of significant concern. The integration of additional cementitious substances into shotcrete could diminish the carbon dioxide output that results from manufacturing standard cement. Earth Friendly Concrete, which doesn’t contain any cement and greatly curtails CO2 emissions, exemplifies how shotcrete might be employed for sustainable building initiatives.

By incorporating industrial residuals such as:

- fly ash

- silica fume

- slag

- metakaolin

As alternative supplementary materials in place of traditional cement, it’s possible to lessen both waste generation and the environmental impact associated with construction activities.

Summary

As we’ve explored, shotcrete is not merely a construction material, but a cornerstone of innovation in modern building techniques. Its versatility, durability, and cost-effectiveness make it an indispensable solution for a wide range of projects, from custom swimming pools to robust retaining walls. The careful selection of a shotcrete contractor and proper maintenance ensure that structures built with shotcrete will stand the test of time, all while minimizing environmental impact. Let this knowledge inspire you to consider the possibilities that SSG Shotcrete offers for your next project.

Frequently Asked Questions

Is shotcrete more expensive than concrete?

Indeed, while shotcrete offers a simpler installation process compared to regular concrete, it does come with a higher cost. Bear in mind the total expense involved when deciding on your choice of material.

Can shotcrete be used for small residential projects, or is it only for large-scale construction?

Indeed, shotcrete is highly versatile and can be employed for even small-scale residential projects. It is quite adaptable and perfect for crafting bespoke features within homes, demonstrating its suitability across a wide range of project sizes.

How do I know if a shotcrete contractor is qualified?

Seek out a shotcrete contractor renowned for their history of successful completions, who possesses the required permits and insurance policies, upholds an exemplary safety record, and comes with commendable endorsements from clients – for instance, SSG Pools.

Such diligence guarantees dedication to excellence as well as contentment among customers.

What is the main advantage of the dry shotcrete process over the wet process?

Utilizing the dry shotcrete process as opposed to its wet counterpart presents a primary benefit in terms of enhanced regulation over the concrete mix. This method permits exact modifications to be made regarding water content directly at the nozzle, which not only contributes to an improved quality finish but also offers economic advantages.

How does shotcrete contribute to environmental sustainability?

By utilizing supplementary cementitious materials and integrating sustainable options such as Earth Friendly Concrete, shotcrete aids in promoting environmental sustainability. It achieves this by diminishing CO2 emissions linked with construction activities, thereby lessening the ecological footprint of building with concrete materials.